Dynamic energy markets and government targets for climate protection are posing challenges for companies across a range of industries. At the same time, the demands and expectations of stakeholders are constantly increasing. In order to systematically boost the energy efficiency of business operations, advanced energy-management methods and professional IT tools are essential.

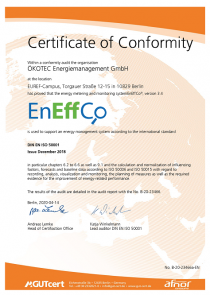

The EnEffCo® solution was developed by industry practitioners for industry practitioners. It enables the comprehensive management of energy efficiency, allowing companies to systematically track, monitor, and evaluate energy system data and processes. Depending on your specific requirements, EnEffCo® can be expanded with additional modules to help you organize tasks, manage individual clients and sites, and view data in new ways. EnEffCo® has been on the market since 2013 and is the established solution at more than 1,000 commercial sites – including more than 100 factories – in Germany and abroad. Notable EnEffCo® customers include BMW, Mercedes-Benz, Speira, and Kerrygold.

The Advantages of Using EnEffCo®

Learn more about EnEffCo®

at one of our free webinars.

The Many Benefits of

Energy Performance Indicators

Companies are often unsure as to whether their systems are energy efficient or whether measures to improve efficiency have been successful. With ÖKOTEC’s targeted energy performance indicators and systematic solutions, you can reliably track the success of your efficiency project goals.

Appropriate for a Variety

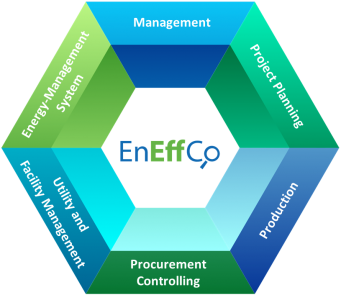

of Application Areas

Software requirements vary depending on their area of application. EnEffCo’s extensive functionality and supplementary modules ensure a results-oriented solution in a variety of domains, including energy and environmental management, facility management, managerial accounting, and production.

Digital Innovation

Working today to create the sustainable products and services of tomorrow: we are already developing the solutions of tomorrow as part of our R&D projects and cooperative activities with clients.

EnEffReg®

Funded by the Federal Ministry for Economic Affairs and Energy (BMWi), this project aims to develop software that can automatically regulate systems according to energy efficiency criteria. The heart of the solution is an intelligent control system based on ÖKOTEC energy performance indicators, statistical methods and artificial intelligence. ÖKOTEC is cooperating with Bayer, Daimler and ThyssenKrupp in this project.

CO2realtime

With “CO2realtime“, companies can reduce their greenhouse gas emissions and save energy costs. One innovative aspect of the project is that the carbon footprint reflects real-time data for specific product. The “Real-time Product Carbon Footprint” project started in 2017 in cooperation with Hydro Rolled Products and with funding from the German Federal Environmental Foundation. The partner for communication is co2online.

Flexibility Management

The expansion of renewable energy in the German power grid offers appealing revenue opportunities for flexible consumption systems to balance out increasingly fluctuating generation. In the industrial sector, it introduces interesting possibilities for production and cross-cutting technologies. ÖKOTEC is testing these possibilities in various R&D projects. In WindNODE (part of BMWi’s SINTEG funding programme), ÖKOTEC is developing the concept of a technical interface for automated flexibility assessment and control and is testing the processes at pilot industrial plants. In “Phi-Factory“, scientists at TU Darmstadt, together with ÖKOTEC and industrial partners, are investigating how the supply of renewable energy can be harmonised with demand.